the fibers

Many times we’ve wondered how the fabrics used to make the clothes we wear or the ones we use to decorate our homes are produced.

To better understand the process, we’ll first talk about textile fibers, which are the fundamental units used to create different textile products.

Textile fibers can be classified into two main families:

Natural Fibers

As the name suggests, natural fibers are obtained from nature and come from animal, vegetable, or mineral sources.

| ANIMAL ORIGIN | VEGETABLE ORIGIN | MINERAL ORIGIN |

| Wool, Silk, Hair, Cashmere, Mohair, Alpaca, Camel | Cotton, Linen, Jute, Esparto, Hemp | Glass, Metallic fibers |

Chemical Fibers

Chemical fibers can be artificial, obtained by transforming tree cellulose, or synthetic, derived from petroleum-based synthesis.

| ARTIFICIAL FIBERS | SYNTHETIC FIBERS |

| Viscose, Lyocell, Alginates, Cellulose Acetate | Polyester, Polyamide, Carbon fiber, Acrylic, Elastomers |

WHAT ARE THE MOST IMPORTANT CHARACTERISTICS OF THESE FIBERS?

All fibers, both natural and chemical, have characteristics that will determine the final product. The most important are:

- Abrasion resistance: the ability to withstand daily friction.

- Pilling: formation of knots or little balls on the fabric surface due to wear.

- Shine: intensity of reflected light on the fabric.

- Elasticity: ability to return to original length after stretching.

- Water absorption: the capacity to absorb moisture. A higher rate means greater comfort.

- Light exposure: effects of sunlight on the fabric (yellowing, breaking strength, abrasion resistance…)

- Shine: The intensity of light reflected on the fiber surface. The rounder the fiber, the more it reflects.

- Fineness and length: determine softness or resistance to tearing.

- Color: the natural fiber color influences its dyeing, printing, and bleaching capabilities.

Each fiber’s origin gives it unique characteristics that determine its use.

The most commonly used natural fibers are:

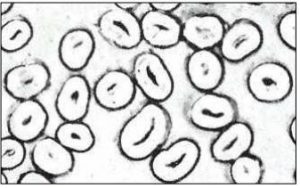

COTTON

Cotton is the most important and widely used natural fiber, obtained from the seeds of plants of the genus Gossypium. Cotton fibers do not mature simultaneously, so once harvested, they vary in length, maturity, and fineness. To standardize these differences, cotton can be mercerized to improve its shine, moisture absorption, and dyeing properties. This process uses caustic soda to swell and soften the fibers, also increasing strength.

Cotton fibers are used alone or blended with chemical fibers for different purposes.

How does it react to flames?

Cotton burns easily but can undergo flame-retardant treatment to delay ignition.

JUTE

Jute is extracted from the plant's stems, which can reach up to three meters tall. It's the most used vegetable-origin fiber after cotton. Being cellulosic, it has similar properties to cotton. It’s used for sacks, ropes, packaging, decorations, and accessories.

Its main drawback is its brown color, which makes it typically dyed in darker tones.

LINEN

Linen fibers are extracted from plants of the “linaceae” family. It is less used today in textiles due to high extraction costs. Linen wrinkles easily, so it’s often blended with chemical fibers to improve ironability.

WOOL

Wool is an exceptional fiber obtained from the fleece of sheep and rams through manual or robotic shearing. It’s classified based on the animal’s quality. Afterward, it is washed due to the high level of impurities in raw wool.

Its main feature is its excellent thermal insulation, which makes it ideal for winter garments. It also conducts heat well and absorbs up to 35% of its weight in water without feeling damp.

Wool's main drawback is its tendency to shrink (felting), especially with machine washing or high temperatures. Special treatments can prevent shrinkage.

SILK

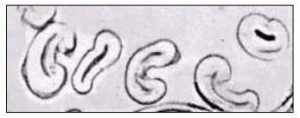

Silk comes from the *Bombyx Mori* (silkworm), whose fiber, known as fibroin, is the only natural continuous filament. These worms feed on mulberry leaves. One month after hatching, they spin cocoons to become chrysalises and eventually butterflies.

Silk is known for its fineness (10–20 microns) and shine. It’s used mainly for clothing and tapestries.

GLASS FIBER

This fiber is obtained by melting various glasses. It is highly resistant to high temperatures and is both non-flammable and incombustible.

SILICON FIBER

These fibers maintain their properties at temperatures up to 1000ºC.

The most used artificial fibers are:

ALGINATES: derived from seaweed, used in bandages and wound care textiles.

VISCOSE RAYON: made from wood cellulose (mainly eucalyptus due to its high yield and fast growth). It tends to shrink after washing.

MODAL: regenerated cellulose fiber made from higher-quality cellulose than viscose, making it more resistant.

Among the most widely used chemical fibers we highlight:

POLYESTER: synthetic chemical fiber derived from petroleum-based polymers.

It has low moisture absorption, which results in poor breathability but quick drying. It tends to form pilling, which can be reduced with treatments like